Export Kitchen Safety Matches: Buy Direct from Trusted Indian Manufacturer

Introduction

In today’s competitive global market, international buyers often struggle to find reliable, certified suppliers of kitchen safety matches. Many worry about inconsistent quality, delays in shipments, or hidden costs from middlemen. That’s why buying directly from a trusted Indian manufacturer is the best way to save costs, ensure quality, and build long-term business partnerships.

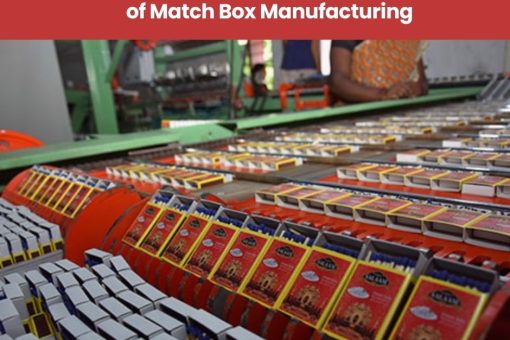

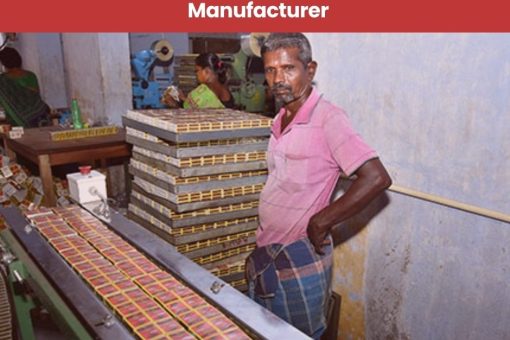

For over 40 years, Quenker Matches, based in Kovilpatti, Tamil Nadu; the central hub of India’s match industry; has been delivering safe, durable, and Kitchen Safety Matches Export to wholesalers, distributors, and importers across Africa, the Middle East, and beyond.

This blog tells you to buy the matchboxes from the trusted Indian Manufacturers, and what are the factors to be considered. Here we go!

India’s Strength in Kitchen Safety Matches Exports

India is widely known as the world’s largest producer and exporter of safety matches. By sourcing kitchen safety matches from India, buyers gain cost benefits, quality, and reliable supply

Cost-effective production: Indian match factories leverage economies of scale.

Skilled craftsmanship: Generations of expertise ensure safe, reliable matches.

Global compliance: Matches meet ISI certification and international safety standards.

Fast shipping: Well-connected ports in Tamil Nadu make global exports seamless.

Bulk supply advantage: Competitive pricing for wholesalers and distributors.

With cost efficiency, skilled production, and global compliance, India has become a top sourcing destination for businesses importing wholesale safety matches with assured reliability.

Trusted Indian Manufacturer for Global Buyers

Wholesale match imports are not just about products; they require trust, reliability, and smooth execution. That’s why we ensure every order comes with:

Verified expertise with decades of manufacturing and export experience.

Stringent quality checks and compliance with international safety certifications.

Hassle-free export process with complete documentation and support.

On-time shipments powered by advanced production capacity.

Competitive factory-direct pricing that ensures better margins for global distributors.

By partnering with an experienced Indian manufacturer, international buyers gain a dependable supply chain of bulk safety matches export that balances quality, affordability, and timely delivery.

Key Factors Before Buying Kitchen Safety Matches

Kitchen matches are an everyday necessity, widely used in homes, restaurants, and commercial kitchens across the world. When sourcing them for wholesale or retail, there are a few important factors to keep in mind:

Matchstick Length – Longer sticks make it easier and safer to light stoves, gas burners, and candles.

Flame Consistency – Matches should ignite quickly and burn with a steady, reliable flame.

Moisture Resistance – A protective coating ensures dependable performance, even in humid environments.

Sustainable Materials – Eco-friendly wood and packaging add value for markets that prioritize environmental responsibility.

Packaging & Branding – Attractive boxes with options for custom branding help products stand out in competitive retail spaces.

By considering these factors, importers and wholesalers can ensure they are investing in safe, reliable, and market-ready kitchen matches suitable for both domestic and international demand.

Benefits of Buying Direct Kitchen Safety Matches

When sourcing kitchen safety matches for wholesale, choosing a direct partnership with a trusted Indian safety matches manufacturer and supplier brings clear advantages:

Factory-Direct Pricing

Eliminate middlemen and reduce unnecessary costs. Buying direct ensures competitive wholesale prices, giving importers better profit margins.

Guaranteed Quality Standards

Every batch is produced under ISI certification and strict quality checks. This guarantees safe, consistent, and reliable matches suitable for global markets.

Customization & Branding Options

From box size and stick length to packaging design and logo printing, direct manufacturers offer tailored solutions to match your market’s needs.

Reliable Supply & On-Time Delivery

With dedicated production capacity and streamlined logistics, trusted manufacturers like Quenker Matches ensure timely deliveries, reducing risks of stockouts.

Hassle-Free Export Process

Exporting wholesale safety matches from India becomes smooth when handled by experienced suppliers. Documentation, compliance, and shipping are managed efficiently, giving buyers a stress-free experience.

Checklist for Kitchen Safety Matches Importers

Factor to Consider

Why It’s Important

What a Trusted Manufacturer Offers

Stick Length & Strength

Longer, sturdy sticks improve usability

Matches designed for safe kitchen use

Flame Performance

Quick ignition and steady burn

Tested under strict quality checks

Moisture Resistance

Ensures usability in humid conditions

Special protective coating applied

Packaging Durability

Boxes should be strong & well-printed

Export-grade packaging with branding options

Certifications

Needed for smooth customs clearance

ISI-certified, export-compliant products

Sustainability

Growing demand for eco-friendly products

Use of responsibly sourced wood & materials

Quenker Matches – Leading Kitchen Safety Matches Exporter

Founded over 40 years ago, Quenker Matches has built its reputation as one of India’s most reliable names in Safety matches manufacturer and exporter.

Based in Kovilpatti, Tamil Nadu, They are expertised in combining traditional craftsmanship with modern technology to produce bulk safety matches export that meet the highest international standards.

Main Strengths:

40+ years of experience in match manufacturing.

Wide product portfolio: kitchen matches, wax matches, wooden matches, veneer matches, cardboard matches, long barbecue matches.

Export presence across Africa, Middle East, South America, and Asia.

Compliance with ISI certification and international safety guidelines.

Dedicated export team to support global buyers.

Known for great customer service and ethical business practices.

These are the main strengths making Quenker Matches a leading Indian safety matches supplier.

Why Quenker Kitchen Matches Stand Out

Kitchen matches play a vital role in everyday life, from lighting stoves and candles in households to igniting burners in restaurants and ensuring smooth operations in commercial kitchens worldwide. Buyers choose Quenker kitchen matches for:

Longer matchsticks – Easy to light stoves, gas burners, and candles.

Steady flame – Lights quickly and burns consistently.

Moisture resistance – Special coating ensures performance in humid climates.

Eco-friendly materials – Produced using sustainable wood and packaging.

Attractive packaging – Custom branding available for wholesale buyers.

This makes our kitchen wholesale safety matches a preferred choice for importers and wholesalers who need reliable, cost-effective products to supply both local retail shelves and demanding international markets.

Conclusion: Partner with Quenker for Kitchen Safety Matches Export

For more than 40 years, Quenker Matches has been a trusted name in India’s match industry, delivering safe, high-quality, and Kitchen Safety Matches Export to buyers worldwide. Certified with ISI certification, built with modern technology, and understanding customer-first values, we ensure every shipment meets global standards of quality, consistency, and reliability, making a leading Safety matches manufacturer.

When you buy direct from us, you are not just importing a product, you are building a long-term partnership with a dependable Indian manufacturer who understands your business needs.

Choose Quenker Matches; where quality meets reliability in every box!